Werner Machine possesses technical expertise and experience to manufacture the most precise and complex parts consistently. Our proficiency in CNC milling, CNC turning, and CNC machining stems from years of hands-on experience. Having designed and manufactured parts ourselves, we understand what it takes to get the job done right. Utilizing cutting-edge technology, rigorous training, and an unwavering pursuit of perfection, we achieve the most consistent parts and tightest tolerances imaginable.

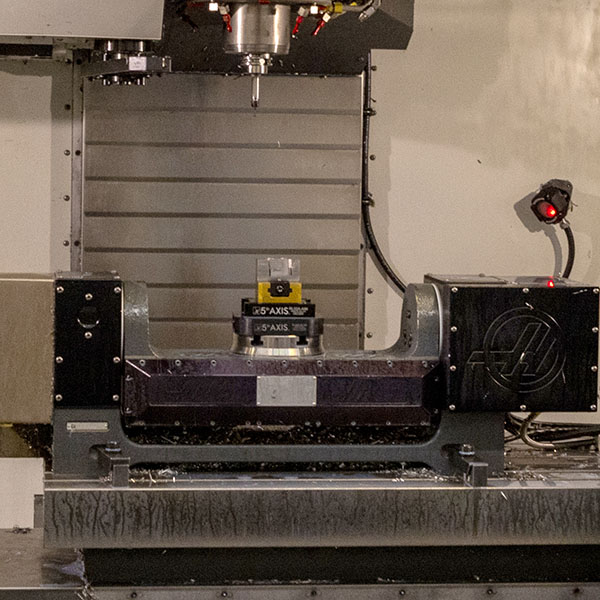

3-Axis CNC Machining

Our facility houses six 3-axis CNC machines, capable of creating cuts in three directions: X-axis (left/right), Y-axis (forward/backward), and Z-axis (up/down). These machines can cut, drill, and mill 2D and 2.5D parts. One machine features a dual-axis trunnion rotary table, enabling it to function as a 5-axis CNC machine.

4-Axis CNC Machining

We utilize 4-axis rotary tables that can be connected to our 3-axis CNC machines, allowing for additional cuts along a fourth axis. This equipment allows the machine to rotate around the A-axis, make angled cuts, create holes, and mill slots at different angles.

5-Axis CNC Machining

For projects requiring the tightest tolerances and the most intricate cuts, we offer 5-axis CNC machining capabilities. The fifth axis allows the CNC machine to cut along the three linear axes (X, Y, and Z), the rotational axis (A), and an additional rotational axis (B). This capability enables the tool to access multiple sides of the part without repositioning, enhancing precision and efficiency in machining complex parts.

CNC Turning

Our facility includes multiple CNC turning machines that automate the turning process, providing precise control over the cutting tool’s movement and speed. These machines facilitate facing, threading, knurling, drilling, and taper turning on various materials.

Lathes

We also maintain manual lathes for quick, one-off projects or small production runs. These hands-on machines allow our team to develop a deep understanding of manual operations, which is essential before transitioning to computerized machines.

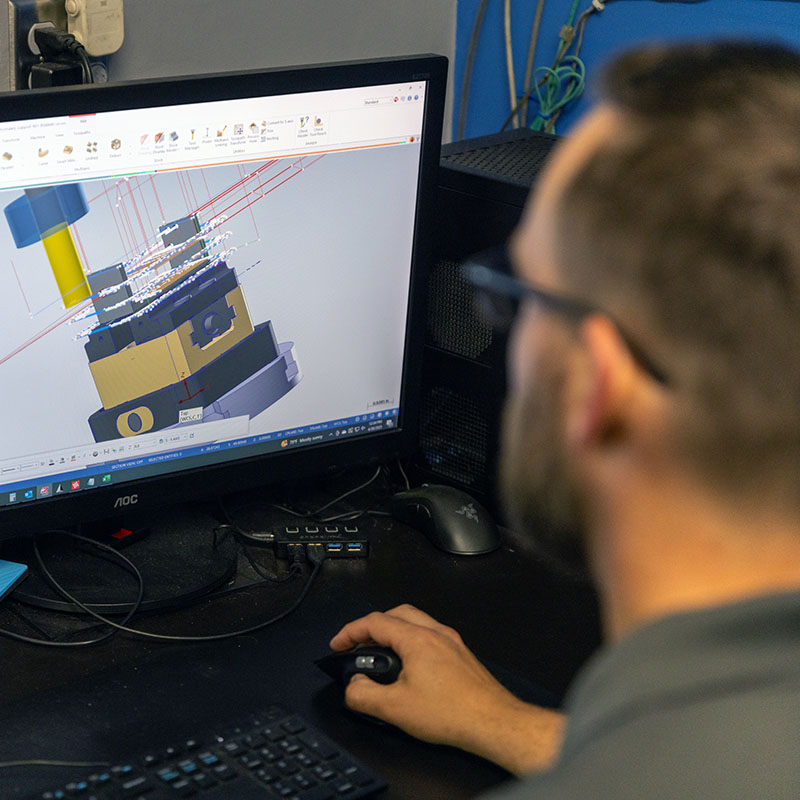

Engineering & Design

Our team includes members with mechanical engineering backgrounds and experience in engineering firms. Having built parts we've designed, we ensure that our customers’ designs are practical and manufacturable. We offer our expertise to improve customer designs, making them more cost-effective and precise, bringing their parts to life.

Equipment List: Proudly Using HAAS CNC Machines and Additional Equipment

-

HAAS VF2 SS

CNC 3-Axis Vertical Milling Machine (Qty 3)

-

HAAS VF3 with TR160 5-axis Trunnion

CNC 3-Axis Vertical Milling Machine with a dual-axis trunnion rotary table

-

H4: HAAS VF4 SS

CNC 3-Axis Vertical Milling Machine

-

H4: HAAS VF9

CNC 3-Axis 82” x 38″ x 28” Vertical Milling Machine

-

HRT210 and HRT160SP

4-axis rotary tables

-

HAAS ST20Y

CNC turning center with live tooling and Y-axis with programmable tailstock

-

HAAS ST20

CNC turning center with programmable tailstock

-

HAAS TL-2

CNC toolroom lathe

-

Software Tools

- Solidworks: CAD software

- Mastercam: CAM software

- Startproto: ERP software